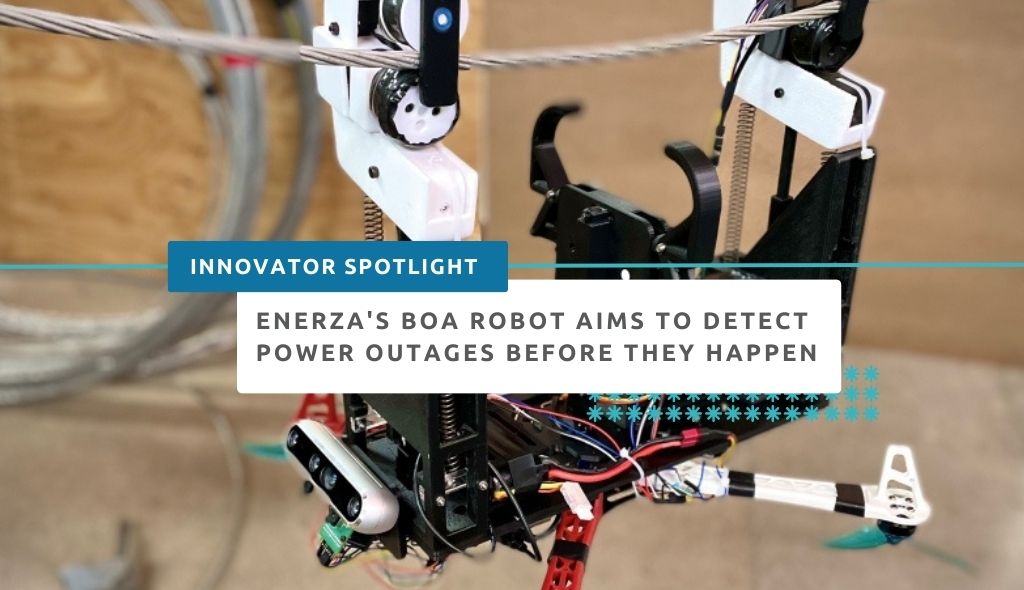

Could robots help detect and prevent power outages before they happen? Innovation Factory and CITM innovator Enerza is poised to make this a reality through their first-in-kind conditional risk assessment tool using autonomous on-wire robotic monitoring.

“We’re trying to do something new that hasn’t been done before,” says Chief Technology Officer, Anson Maitland. “By having a device like this you are removing workers from dangerous work environments.”

Advancing safety through grid analytics innovation

Safety and efficiency, two pillars that underpin the utility sector, stand to benefit profoundly from Enerza’s innovation, the BOA.

At the core of Enerza’s mission lies the desire to revolutionize the methodologies employed by electrical utility providers for risk assessments, particularly concerning the inspection of overhead wires. The data harvested by the robot serves as the bedrock for a transformative collaboration between grid analytics and autonomous technologies.

“The most common inspection method now is primarily done manually. People go out in rural areas, they have to go out in ATV trucks, and they’re basically inspecting the line visually,” Maitland explains.

This exposure to treacherous landscapes and unpredictable weather conditions increases the likelihood of accidents. Workers also encounter dangers like electrocution, falls from heights, and interaction with hazardous wildlife.

Enerza’s approach helps mitigate such risks, ensuring precise assessments and revolutionizing power line inspection safety and efficiency.

Automating precision for enhanced reliability

The foundation of Enerza’s innovation rests upon automation, a concept that not only addresses human error but also addresses safety apprehensions.

While the BOA robot remains in the developmental phase, its capabilities are already remarkable. It has the ability to detect encroaching vegetation, such as branches or leaves, that might compromise the integrity of the wires. Moreover, BOA can identify signs of failing infrastructure; a critical factor in preventing potential disasters.

“[The robot] would be able to use the propellers to fly itself up to the line and would be able to attach the line,” said Maitland. “[It would use] things like thermal cameras, depth cameras, and then a combination of other stereoscopic cameras in order to measure distances.”

Data-driven prediction: Preventing power outages

One crucial goal is predicting power outages before they materialize. Enerza’s innovation hinges on its ability to collate, process, and interpret the information obtained during inspections.

Maitland elaborates on the post-inspection process, “Once that information is collected, it’s fed back to a database to determine if there’s an issue now or if one could develop in the coming weeks.”

However, the company is still refining their solution to navigate insulators and other obstacles on the line. The concept of a robot nimbly navigating across power lines is not devoid of challenges. The navigation aspect is pivotal. It underscores the aspiration to render the robot versatile, capable of maneuvering effortlessly in environments that were once deemed inaccessible.

“Which is something that hasn’t been done before and something that we’re keen to develop,” said Maitland.